Aumento de la confiabilidad del plan minero

Overview

La mina Collahuasi es una de las más grandes minas ubicadas en gran altitud en el norte de Chile en la región de Tarapacá. Collahuasi representa una de las más grandes reservas de cobre en el mundo y es operada por un joint Venture entre Anglo American (44%), Glencore (44%) y Japan Collahuasi Resources (12%). El equipo de gestión mina en Collahuasi buscaba mejorar la confiabilidad de sus planes mineros de corto plazo en 2018. En particular, ellos requerían una metodología para modelar la variabilidad de su proceso de carguío y transporte para obtener planes más precisos. Además, la gerencia mina buscaba identificar planes alternativos que pudiesen agregar más valor a la operación.

Solución

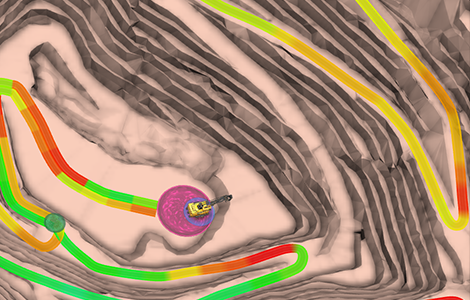

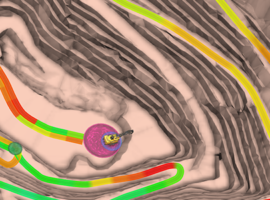

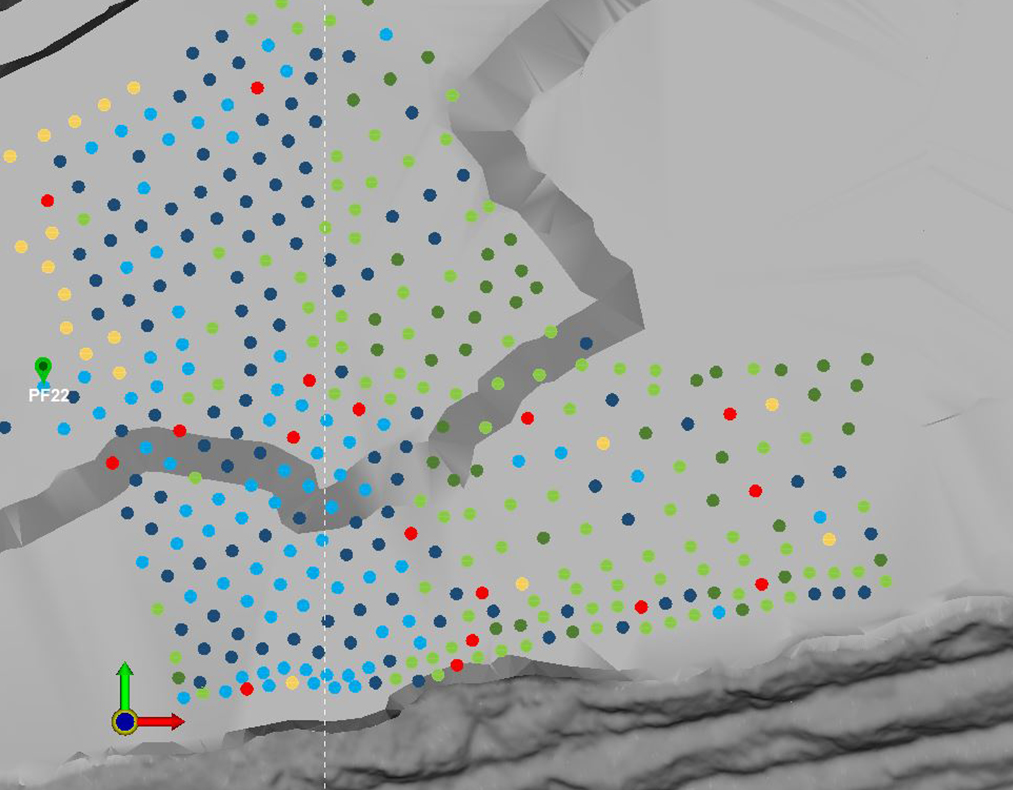

El equipo de planificación de corto plazo de Collahuasi implementó la metodología de simulación en toda su planificación de corto plazo con el propósito de evaluar la confiabilidad e identificar oportunidades de mejora. Las simulaciones fueron llevadas a cabo usando TIMining Orchestra, el cual es un software creado especialmente para simular el proceso de carguío y transporte. La metodología fue la siguiente:

- TIMining Orchestra se conecta automáticamente a la base de datos del Sistema de Gestión de Flota.

- Análisis de la data histórica del proceso de carguío y transporte fue realizado para crear los inputs para la creación del modelo de simulación.

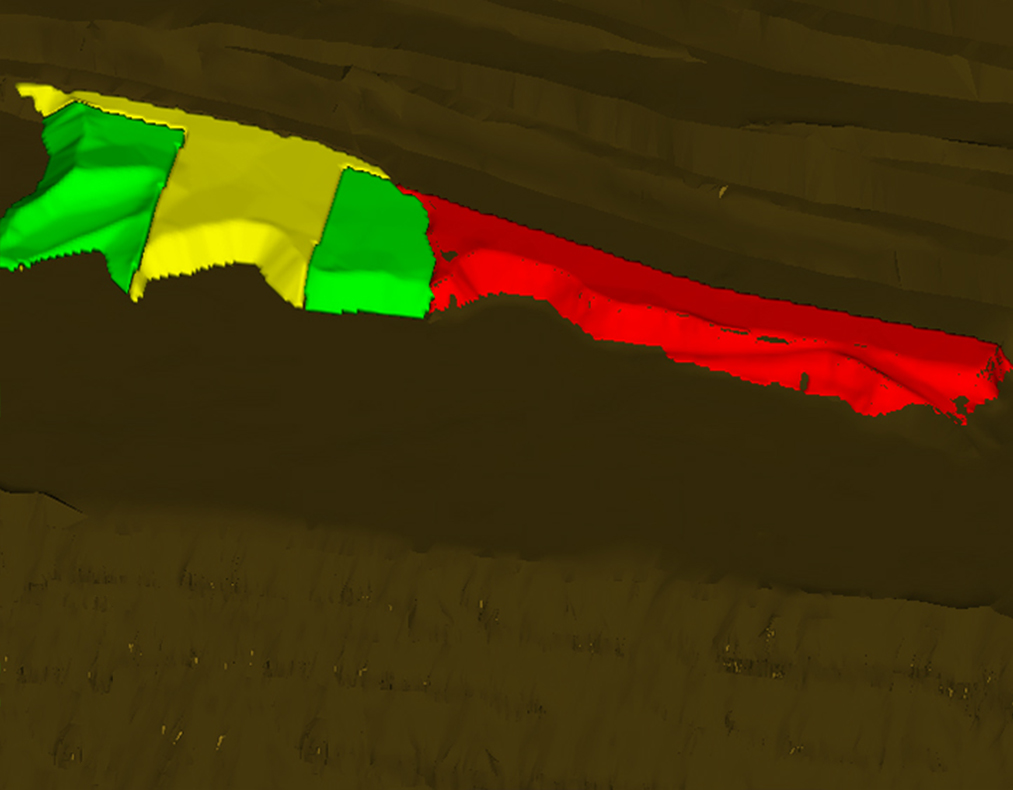

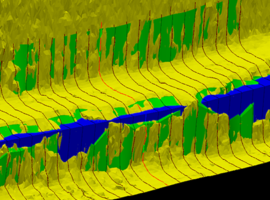

- Modelos de simulación creados a partir de data real de la operación.

- Simulación de planes de corto plazo i.e. semanales y mensuales, además de planes alternativos, para identificar oportunidades de mejora y mitigación de riesgo.

- Los modelos son continuamente actualizados y los planes son sometidos a una evaluación rigurosa para verificar su confiabilidad, encontrar alternativas y optimizaciones.

Impacto

Hoy, los planes de corto plazo de la mina Collahuasi están siendo más precisos mediante el uso de simulaciones. El equipo de gestión mina puede estimar el cumplimiento de sus planes mineros con una desviación bajo el 2%.

Como beneficios adicionales se han:

- Identificar e implementar mejores alternativas para descarga en botaderos.

- Identificar alternativas para rutas de transporte más rápidas y reducción de tiempos de ciclo.

- Evaluar diferentes estrategias para la ubicación de la flota de transporte y mantenciones de equipos mayores.

- Actualizar inputs para la planificación de largo plazo.

- Cuantificar el impacto de eventos geotécnicos en la operación.

PRODUCTOS RELACIONADOS

Drillit

Monitoreo del proceso de Perforación y Tronadura, QA/QC automático y conciliación de los planes de perforación.